BS5308

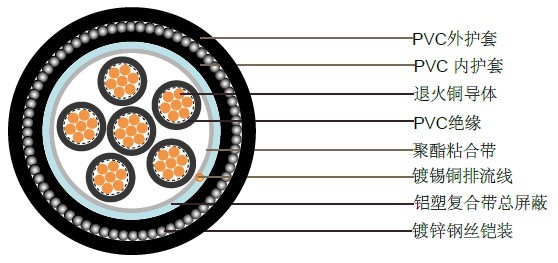

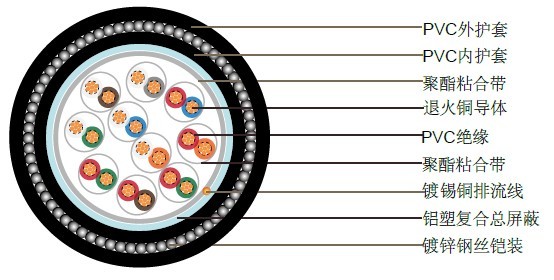

第二部分2类 (铠装电缆) PVC绝缘+总屏蔽+铠装+PVC护套

多芯

多对

多对

应用

特点

- 经济

- 柔软 易安装

产品结构

| 导体 | 退火铜或镀锡铜, 尺寸: 遵循BS6360标准,0.5mm²和0.75mm²,5类多股,1.5mm²,2类多股铜 | |

| 绝缘 | PVC(聚氯乙烯), 遵循BS6746标准,TI1类 | |

|---|---|---|

| 成对 | 两芯对绞,加小于100mm的隔离带 | |

| 线对颜色 | 多芯电缆: 40芯以下黄色(带有黑色数字编码), 41-80芯黑色(带有黄色数字编码). 多对电缆:参照附注里的色彩编码 | |

| 粘合带 | 透明的聚合酯带 | |

| 总屏蔽 | 铝塑复合屏蔽,金属面向内,紧挨0.5mm²的排流线 | |

| 内护套 | PVC(聚氯乙烯), 遵循BS6746标准,TM1类 | |

| 铠装 | 镀锌钢丝铠装 | |

| 外护套 | PVC(聚氯乙烯)护套,遵照BS6746标准,TM1类或6类 | |

| 护套颜色 | 黑色/蓝色 |

技术参数

| 标称电压 | Uo/U 300/300 V |

|---|---|

| 测试电压 | 芯/芯 2000 V |

| 弯曲半径 | 固定敷设:4X d 灵活应用:6X d |

| 温度范围 | 固定敷设:-40/+70℃ 灵活应用:-0 / +50°C |

| 短路温度 | +160º C |

| 阻燃 | 符合 IEC 60332.1 |

| 绝缘电阻 | 20 MΩxkm |

| 耐候性 | 一般 |

| 机械特性 | 一般 |

| 环保 | 符合欧盟RoHS指令 |

电缆参数

对数 | 导体 | 标称 | 标称 | 标称 | 标称 | 标称 | 标称 | 标称 | 标称 |

| no./mm | mm2 | mm | mm | mm | mm | mm | mm | kg/km |

2 | 24/0.2 | 0.75 | 0.6 | 0.8 | 7.2 | 0.9 | 1.3 | 11.2 | 280 |

3 | 24/0.2 | 0.75 | 0.6 | 0.8 | 7.2 | 0.9 | 1.3 | 11.6 | 305 |

4 | 24/0.2 | 0.75 | 0.6 | 0.8 | 7.8 | 0.9 | 1.3 | 12.4 | 335 |

6 | 24/0.2 | 0.75 | 0.6 | 0.9 | 9.4 | 0.9 | 1.4 | 14 | 400 |

10 | 24/0.2 | 0.75 | 0.6 | 1.1 | 12.2 | 0.9 | 1.5 | 17 | 565 |

20 | 24/0.2 | 0.75 | 0.6 | 1.2 | 15.6 | 1.25 | 1.6 | 21.3 | 950 |

40 | 24/0.2 | 0.75 | 0.6 | 1.3 | 20.6 | 1.6 | 1.7 | 27.4 | 1590 |

80 | 24/0.2 | 0.75 | 0.6 | 1.5 | 28.5 | 1.6 | 1.9 | 35.7 | 2450 |

2 | 7/0.53 | 1.5 | 0.6 | 0.8 | 8 | 0.9 | 1.4 | 12.6 | 330 |

3 | 7/0.53 | 1.5 | 0.6 | 0.9 | 8.2 | 0.9 | 1.4 | 12.8 | 380 |

4 | 7/0.53 | 1.5 | 0.6 | 0.9 | 9 | 0.9 | 1.4 | 13.6 | 420 |

6 | 7/0.53 | 1.5 | 0.6 | 1.1 | 11 | 0.9 | 1.4 | 15.6 | 540 |

10 | 7/0.53 | 1.5 | 0.6 | 1.2 | 14 | 1.25 | 1.6 | 19.7 | 750 |

20 | 7/0.53 | 1.5 | 0.6 | 1.3 | 17.9 | 1.6 | 1.7 | 24.5 | 1260 |

40 | 7/0.53 | 1.5 | 0.6 | 1.5 | 24 | 1.6 | 1.9 | 31 | 2140 |

80 | 7/0.53 | 1.5 | 0.6 | 1.7 | 32.9 | 2 | 2.1 | 41.1 | 3300 |

对数 | 导体 | 标称 | 标称 | 标称 | 标称 | 标称 | 标称 | 标称 | 标称 |

| no./mm | mm2 | mm | mm | mm | mm | mm | mm | kg/km |

1 | 16/0.2 | 0.5 | 0.6 | 0.8 | 6.2 | 0.9 | 1.3 | 10.6 | 260 |

2 | 16/0.2 | 0.5 | 0.6 | 0.8 | 7.1 | 0.9 | 1.3 | 11.5 | 305 |

5 | 16/0.2 | 0.5 | 0.6 | 1.1 | 12.4 | 0.9 | 1.5 | 17.2 | 610 |

10 | 16/0.2 | 0.5 | 0.6 | 1.2 | 16.5 | 1.25 | 1.6 | 22.2 | 1060 |

15 | 16/0.2 | 0.5 | 0.6 | 1.3 | 19.2 | 1.6 | 1.7 | 25.8 | 1330 |

20 | 16/0.2 | 0.5 | 0.6 | 1.3 | 21.7 | 1.6 | 1.8 | 28.5 | 1800 |

30 | 16/0.2 | 0.5 | 0.6 | 1.5 | 26.4 | 1.6 | 1.9 | 33.4 | 1980 |

50 | 16/0.2 | 0.5 | 0.6 | 1.7 | 33.4 | 2 | 2.1 | 41.6 | 3070 |

1 | 24/0.2 | 0.75 | 0.6 | 0.8 | 6.7 | 0.9 | 1.3 | 11.1 | 305 |

2 | 24/0.2 | 0.75 | 0.6 | 0.8 | 7.7 | 0.9 | 1.4 | 12.3 | 360 |

5 | 24/0.2 | 0.75 | 0.6 | 1.2 | 13.8 | 1.25 | 1.5 | 19.3 | 820 |

10 | 24/0.2 | 0.75 | 0.6 | 1.3 | 18.4 | 1.6 | 1.7 | 25 | 1250 |

15 | 24/0.2 | 0.75 | 0.6 | 1.3 | 21.1 | 1.6 | 1.8 | 27.9 | 1600 |

20 | 24/0.2 | 0.75 | 0.6 | 1.5 | 24.4 | 1.6 | 1.8 | 31.2 | 1800 |

30 | 24/0.2 | 0.75 | 0.6 | 1.7 | 29.6 | 2 | 2 | 37.6 | 2570 |

50 | 24/0.2 | 0.75 | 0.6 | 2 | 37.4 | 2.5 | 2.3 | 47.3 | 3800 |

1 | 7/0.53 | 1.5 | 0.6 | 0.8 | 7.5 | 0.9 | 1.4 | 12.1 | 360 |

2 | 7/0.53 | 1.5 | 0.6 | 0.9 | 8.8 | 0.9 | 1.4 | 13.4 | 460 |

5 | 7/0.53 | 1.5 | 0.6 | 1.2 | 15.6 | 1.25 | 1.6 | 21.3 | 1040 |

10 | 7/0.53 | 1.5 | 0.6 | 1.3 | 20.9 | 1.6 | 1.8 | 27.7 | 1610 |

15 | 7/0.53 | 1.5 | 0.6 | 1.5 | 24.6 | 1.6 | 1.9 | 31.6 | 2060 |

20 | 7/0.53 | 1.5 | 0.6 | 1.5 | 27.8 | 1.6 | 2 | 35 | 2630 |

30 | 7/0.53 | 1.5 | 0.6 | 1.7 | 33.7 | 2 | 2.1 | 41.9 | 3460 |

50 | 7/0.53 | 1.5 | 0.6 | 2 | 43 | 2.5 | 2.4 | 52.8 | 5520 |

| 发送询问 |